|

|

Custom Thermoformed Containers |

|

The Best Choice, GRIP B

|

Designers

|

|

GRIP B designer team is very experienced with thermoformed packaging. With many years experience we can finish the task in a short time then get the mock up output. Our CNC machine and small specific thermoforming machine for mock up production also are the best support for the custom project development. If necessary, 7 days later after drawing confirmation, you can see the 1st mock up.

Which Materials GRIP B Provided?

Regular Plastic

Regular PET/PP/PE are all we can thermoform and develop for customers. Besides APET, we also have the solution of CPET that we can support our customer.

Post Consumer Recycled (PCR) Plastic

Like PCR PET and PCR PP, we offer GRS and SCS certificated materials and sheets for carbon reduction packaging.

Compostable Materials

PLA, PBAT+PBS with startch material is the compostable solution we offer for green packaging and thermoforming.

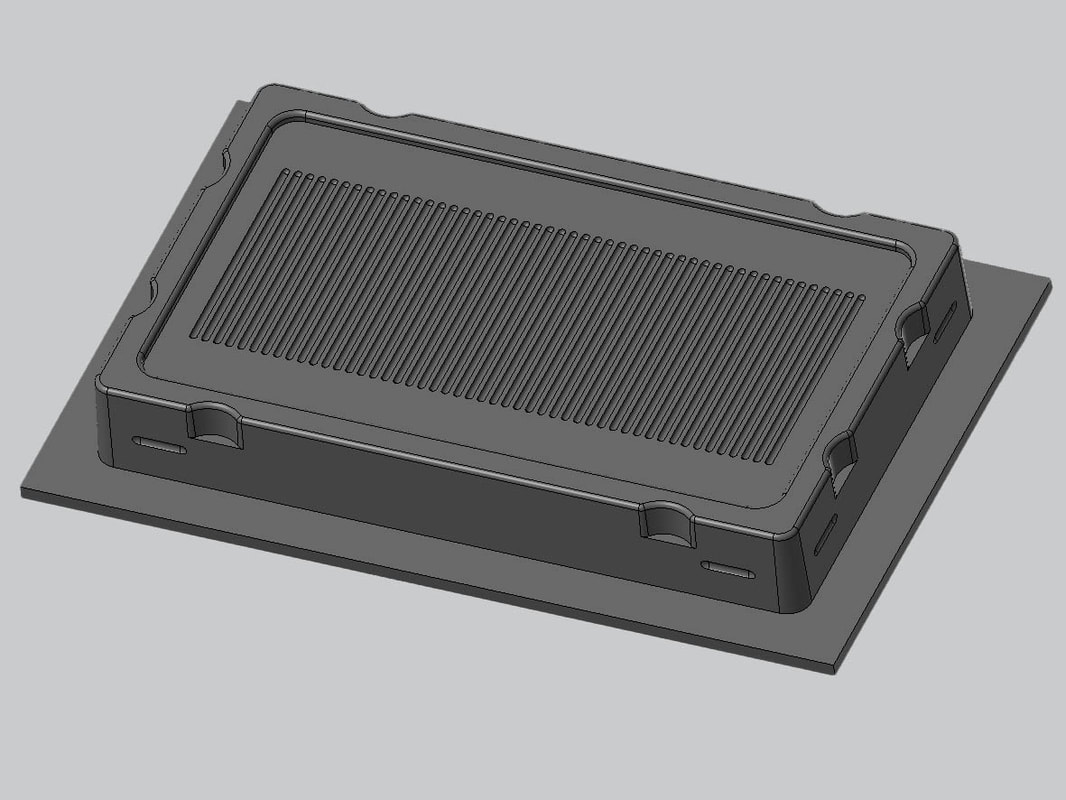

The Process of Custom Containers

1. Quote |

2. Confirm Drawing |

3. Mock Up Output |

4. Mass Production |

When we received your inquiry, we will start the discussion with you.

Once the customer decide to kick off the custom container project after confirm the quotation.

Then we will provide 2D/3D drawing based on customer's request. As long as the confirmation of the drawing finished, next stage we will make a mock sample for customer to check.

If everything goes well, the final mass production will follow the latest mock up to start.

Once the customer decide to kick off the custom container project after confirm the quotation.

Then we will provide 2D/3D drawing based on customer's request. As long as the confirmation of the drawing finished, next stage we will make a mock sample for customer to check.

If everything goes well, the final mass production will follow the latest mock up to start.